By: Nick Gambino

3D printing has been steadily gaining in popularity over the past decade, but it’s far from a ready-to-be-integrated technology. Meaning, we’ve failed to see its adoption into our everyday lives. This might change if a new sustainable option takes off.

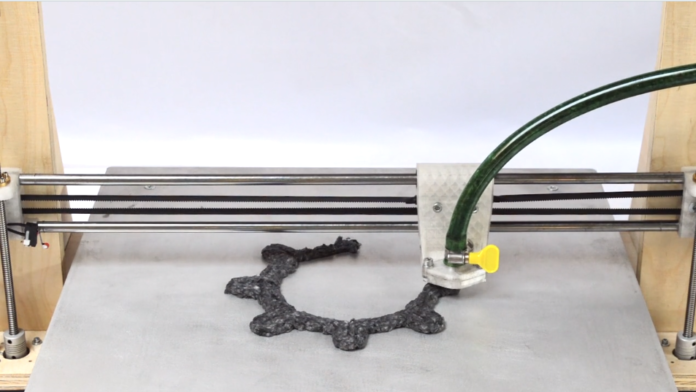

A product designer from the Netherlands, Beer Holthuis, has developed a 3D printer that utilizes wet paper pulp to create its designs. Nearly all 3D printers use a plastic material, which is hardly sustainable. He settled on paper pulp after searching for an alternative material that wouldn’t create any waste. According to Holthuis, we see 80 kg of wasted paper per person each year.

“The design of the printed objects are using the possibilities and beauty of this technique,” Holthuis told 3DPrint.com. “The tactile experience, bold lines and print speed results in distinctive shapes. The objects are durable: Printed paper is surprisingly strong.”

The printer uses a natural binder to ensure all of the layers stick together. It also ensures the product creates a completely recyclable object. These “print-outs” are less refined than objects made through 3D printers that use plastic. They’re less smooth and resemble something on the order of a woven rug or quilt. They’re charming for sure, but will most likely be relegated to knick-knacks and art.

The coolest part of the whole thing is that it’s been designed to accept paper directly which it will then mush into pulp before pushing it out into a design. It’s basically the coolest shredder you’ll ever own. It bypasses the recycling bin, the recycling truck and the recycling facility. You’re basically Captain Planet right now.

Once you tire of the object itself, you can once again recycle it. Though this time you should probably just throw it in the blue bin.

Unfortunately, it’s barely in the prototype stage. Holthuis has thrown together a jerry-rigged 3D printer that’s been altered to accept his sustainable material. It’s not clear if he figured out how to make sure it doesn’t begin to gunk up with the wet pulp.

If this new method catches on it would mean cheaper and more sustainable 3D printing. This could open the door for wider adoption of the tech, as long as they can figure out how to make it look more refined.

ABOUT THE AUTHOR

![]() Nick Gambino is a regular script writer and tech beat reporter for NewsWatch. He lives in Northern Virginia with his wife and daughter.

Nick Gambino is a regular script writer and tech beat reporter for NewsWatch. He lives in Northern Virginia with his wife and daughter.