Laser cutting technology has revolutionized manufacturing, crafting, and hobbyist projects, offering precision and versatility across various materials. With increasing popularity, it’s essential to understand the different types of laser cutters available to choose the right one for your specific needs. This article explains the main types of laser cutters and what to consider when selecting one.

- CO2 Lasers

CO2 lasers are among the most versatile and widely used laser cutters. They work by passing an electric current through a gas mixture containing carbon dioxide, which produces a laser beam. CO2 lasers are capable of cutting, boring, and engraving a variety of non-metal materials, including wood, acrylic, plastics, textiles, and paper. These lasers come in different power ranges, making them suitable for both hobby-level and industrial applications.

- Fiber Lasers

Fiber lasers are known for their efficiency and precision, particularly in metal engraving and marking. These lasers generate a high-intensity beam that’s ideal for creating permanent marks on metal surfaces. Fiber lasers are often used with rotary attachments to mark cylindrical metal objects, expanding their versatility. A fiber laser can penetrate metals more easily than a CO2 laser because the focal point is much smaller, meaning the laser beam is denser and more concentrated. While standard fiber lasers between 20W to 50W cannot cut metal, an extremely potent fiber source of around 2000W can.

- Diode Lasers

Diode lasers are compact, energy-efficient, and versatile, making them a popular choice among hobbyists and small businesses. These lasers use semiconductor diodes to produce the laser beam.

- Nd:YAG Lasers

Neodymium-doped yttrium aluminum garnet (Nd:YAG) lasers are used for boring and engraving, especially in applications requiring high power. They are also suitable for welding.

- Machine Configurations

Industrial laser cutting machines come in three primary configurations:

- Moving Material: These systems have a stationary cutting head, and the material moves beneath it. This setup ensures a constant distance between the laser and the workpiece, simplifying the removal of cutting residue.

- Hybrid: Hybrid lasers feature a table that moves along one axis (typically the X-axis), while the cutting head moves along the shorter Y-axis.

- Flying Optics: In flying optics systems, the laser head moves in both the X and Y axes, allowing for greater flexibility in cutting complex shapes.

- Factors to Consider When Choosing a Laser Cutter

Selecting the right laser cutter involves several considerations:

- Material Compatibility: CO2 lasers are generally better for non-metals, while fiber lasers excel with metals.

- Power Requirements: Higher power lasers can cut through thicker materials more quickly.

- Budget: The cost of laser cutters varies widely, from a few thousand dollars for hobbyist models to tens of thousands for industrial machines.

- Application: Consider whether you’ll primarily be engraving, cutting, or marking when making your selection.

Conclusion

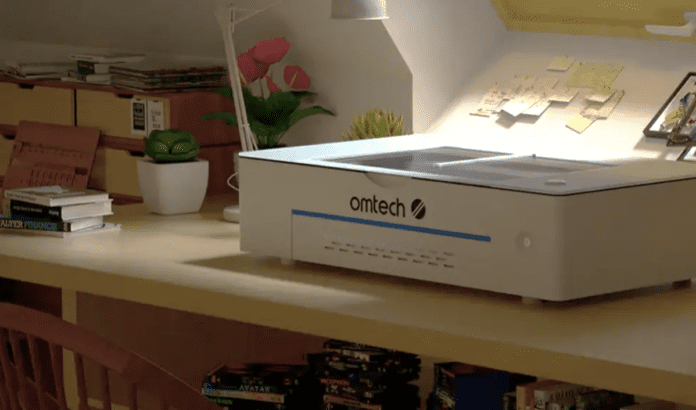

Understanding the different types of laser cutters is crucial for making an informed decision based on your specific needs and applications. CO2 lasers offer versatility for non-metal materials, while fiber lasers are ideal for metal engraving and cutting. Diode lasers provide a compact and energy-efficient option for hobbyists. When choosing a laser cutter, consider the material, power, budget, and application to ensure you select the best machine for your projects. Brands like OMTech offer a range of laser cutters, including CO2 and fiber lasers, designed to cater to various needs and budgets. You can always find you ideal laser cutter at OMTech to unlock your creative potential!