By: Megan Ray Nichols

We’re living in interesting times! Just a generation ago, technologies like the Replicator, seen on Star Trek and similar space operas, seemed hopelessly out of reach. Now, thanks to 3D printing, we’re inching ever closer to consumer-level technology that can produce mechanical parts and even human tissues from raw materials.

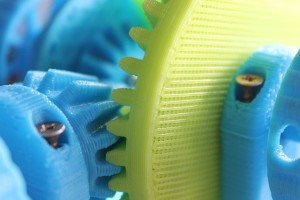

The question that’s emerged, naturally, is how well these 3D-printed parts hold up against their “traditionally” manufactured counterparts. In our conversation today, we’ll focus specifically on gears, since they’re present in many different types of modern machines.

How Well Do They Perform?

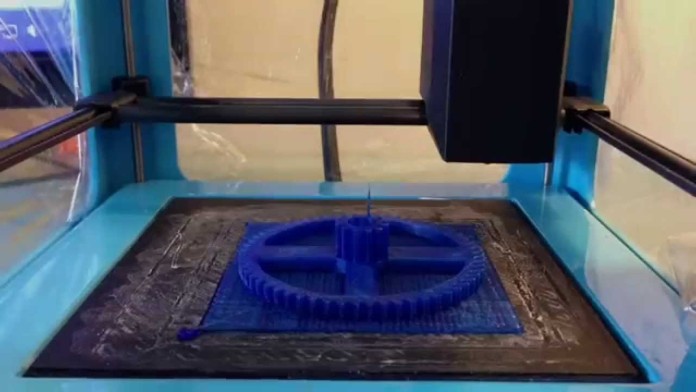

3D-printed gears are catching on as a popular “proof of concept” for 3D printing enthusiasts, most obviously because they require a high degree of precision to work as intended. As you can tell from some of the more popular YouTube videos, this level of precision is becoming somewhat easier to attain even with some of the consumer-level 3D printers.

There’s still a long way to go. Gears printed with a low error tolerance appear to work reliably and smoothly. In the video linked above, they situate the gears with a distance of 0.3 millimeters between them, and can finish almost a complete rotation before encountering any unwanted resistance. When you reduce the distance between the gears, the reliability of their operation does appear to suffer.

The other factor to consider here, of course, is the durability of the material. 3D printers use either ABS or PLA plastic, which are not nearly as durable as metal. Both types of plastic have known difficulties when it comes to 3D printing, including potential “curling” and “warping” when they come into contact with the printer’s heated elements.

Compare this with the alloy steels or cast iron commonly used in the manufacture of “traditional” gears, and you start to get a sense of how far 3D printing has to go before it can compete with traditional materials. With machines consisting of multiple parts, including tooling and attachments, gears might be a quick fix for a replacement, but inefficient for the long haul. 3D-printed gears have a variety of uses, but it’s going to be quite some time before we begin to see them applied to industrial or commercial purposes.

Nevertheless, gears manufactured from other plastics, such as polyamides, do have a number of important benefits over their metal counterparts, including noise generation, vibration dampening and corrosion resistance.

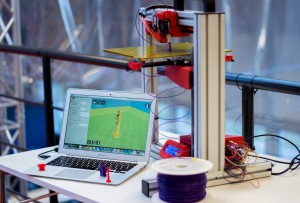

The bottom line, it depends on three factors. The first is the quality of your equipment. While 3D printing is approaching the all-important “consumer-level” price point, a $500 printer is just not going to produce a product that will hold up against years of use and abuse. The second factor is the style of gear. Gears with straight teeth will generally perform better than other styles, whether they’re 3D-printed or manufactured via traditional methods.

The third and final factor is how to use these plastic gears. If you intend on putting them to work meshing with metal gears, for example, you can expect a further reduction in their longevity.

What Are the Practical Uses of Printed Gears?

The hobbyist might be able to find plenty of practical uses for homemade, 3D-printed gears.

As a proof of concept, 3D-printed gears are extremely exciting. Homemade gears are capable of generating great force and torque in all-plastic machines, although practical applications appear to be somewhat hard to come by. Other applications are equally abstract, with gears finding homes in pieces of art, puzzles, and even jewelry.

Nevertheless, gears created with a 3D printer have a variety of uses, albeit fairly “niche” ones — at least for now. Hobbyists and DIYers on Reddit, among other places, are putting their 3D printers to work replicating small mechanical parts that have broken or gone missing. Children’s toys, like RC cars, as well as more “grown up” toys like drones, all make use of small mechanical parts, and 3D printing is providing a way to replace them with relative ease.

It won’t be long before Americans everywhere are manufacturing replacement parts of all shapes and sizes — and gears are only the beginning.

Can “Regular People” Make These Gears?

The answer, thrillingly, is yes. 3D printers are awakening the engineer’s disposition in inquisitive minds all across this country. Websites like Shapeways, 3Dwarehouse and Instructables already have a wealth of resources available for people who are interested in creating simple machines using 3D printers.

We have, in a sense, “democratized” the manufacturing process, and it won’t be long before our ABS and PLS plastics give way to more durable and longer-lasting materials, such as those used in the now-famous 3D-printed bridge under construction in Amsterdam. For the time being, the cost of the raw materials is prohibitive even for affluent DIYers, but it won’t be long before even this barrier to entry gives way. We’re living in the future, folks.

Great blog!

Wonderful site. Lots of useful information here.

After considering several of the blog posts in your website, I truly appreciate your

way of writing a blog. I book-marked it to my bookmark website list and are checking back soon. Please check out

my website too and inform me your emotions.

Ahaa, its fastidious dialogue about this article here at this particular internet

site, We have read all that, so now me also commenting here.

http://20mgprednisone-online.org/ – Prednisone http://cialis20mg5mg.net/

I love it when individuals gathering and share thoughts.

Great blog, ensure that it stays up!

It’s very straightforward to discover any matter on net when compared with

books, because i found this post at this particular web site.

Howdy I am so excited I found your web site, I really found you by

accident, while I was browsing on Bing for something

else, Nonetheless I am here now and would just like to say kudos for a tremendous post and a all round

interesting blog (I also love the theme/design), I don’t

have time to go through it all at the minute but I have book-marked it

and also added in your RSS feeds, so when I have time I will be back

to read a lot more, Please do keep up the excellent job.

I just want to mention I am just very new to blogs and definitely liked you’re web site. Very likely I’m likely to bookmark your website . You really come with perfect well written articles. Thanks for sharing your webpage.

Excellent post. I’m experiencing many of these issues at the same time..

What a stuff of un-ambiguity and preserveness of valuable knowledge regarding unpredicted emotions.

I am certain this component of writing has touched each

of the internet people, its really really fastidious

component of writing on building up new

webpage.

Can I simply say what a comfort to find someone

who actually knows what they are discussing on the internet.

You definitely know how to bring an issue to light and make it important.

A lot more people have to read this and understand this side

of the story. It’s surprising you aren’t more popular given that you surely possess the gift.

Good day very nice web site!! Man .. Beautiful ..

Wonderful .. I will bookmark your blog and take the feeds additionally?

I am glad to seek out numerous useful information here within the submit, we need

work out more strategies on this regard, thanks for sharing.

. . . . .